Experience and Expertise coupled

with High Technological Strength

in producing High Precision Products.

Die-casting is a manufacturing process that makes use of tooling dies, producing geometrically complex metal parts. Inside the die-casting machine, die-casting makes use of molten metal, which is injected at high pressure into the die. The castings can vary greatly in size and in weight. Engine components, pump components, and appliance housings are examples of die-casting. Several automobile components are also manufactured using die-casting. Specifically, the Aluminum die-casting is friendly to the environment since the low density of alloys can reduce wastes and scrap materials can be recycled.

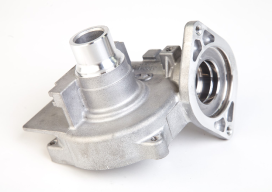

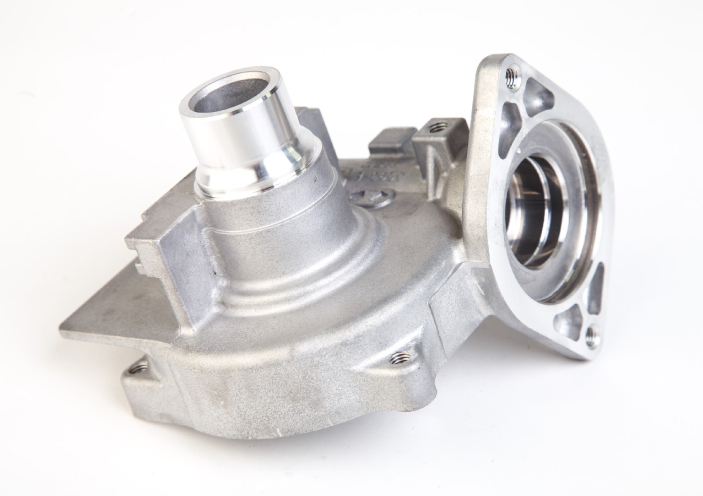

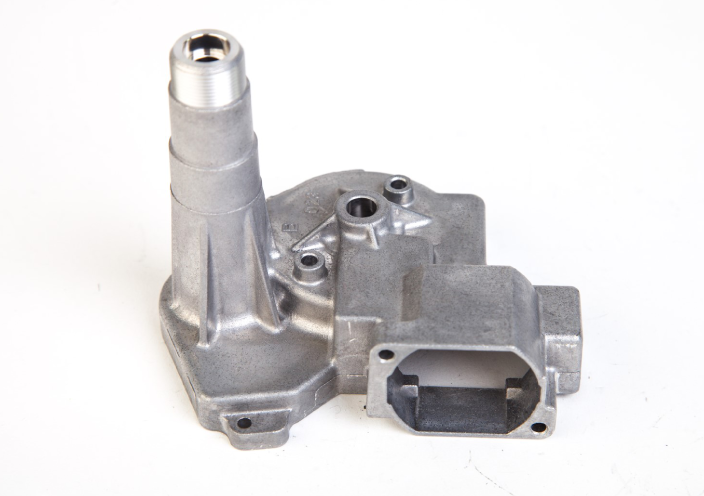

Automobile-Related Parts

Special features of Aluminum die-casting are high dimensional stability, high strength, low density, etc.

High percentage of scrap can be recycled. With these special features, the company continuously engages in the manufacturing and technological advancement of several automobile component parts.

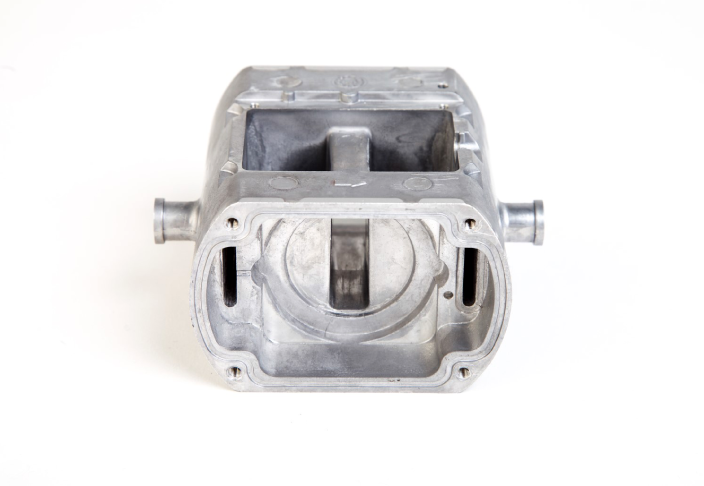

Gear Box for Power Steering

Gear Box Cover for Power Steering

Housing for Power Steering

Column Assembly for Power Steering

Rear Wiper Frame

Front Wiper Frame

Industrial Parts & IT Parts

Low density and yet with high strength, aluminum die-casting also applies to the production of component parts used for camera, video, office automation gadgets, personal computers. Aluminum die-cast parts are also widely adopted for equipment where heat dissipation measures are indispensable.

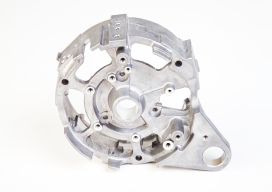

Frame for Fuel Cell

Bracket Rear for Alternator

Quality Policy

Quality Policy

We strive to keep our status as a global partner. We are committed to:

- Conduct the Product Safety Launch during the Pre-Production Period

- Implement 3Ps (Product, Place, People) or the 3Gs

(Gembutsu, Gemba, Genjitsu) as a tool of analysis - Provide learning and training opportunities to our employees

for their constant personal and professional development

Junichi Roppongi

Junichi Roppongi

Representative Director, Gunma Gohkin Co., Ltd.